Project Overview

Earthquakes in the affected zones pose a serious threat to residential buildings. Various methods were developed to mitigate the effects of seismic forces, of which base isolators yield excellent performance for medium-sized buildings located in firm soil. Implementing the Base Isolator Bearing system has proved to be an effective method in preserving the building as those were rigorously studied for more than twenty years, yet the average cost of installation ranges between $33k to $200k. Many developing countries find the technology inaccessible purely because of the associated cost. The material cost of the rubber used in systems takes a crucial share of that price range. Alternatives to the natural rubber used in the standard systems are proposed in Eco-friendly Scrap Tyre Rubber Pads (STRPs), where the natural rubber is replaced with automobile tire scraps. Comparing the performance of STRPs in terms of their ability to withstand a range of seismic forces and standard systems can illustrate whether alternative materials can be used effectively and thus implemented for cost reduction. The STRPs alternative is not only promising for cost reduction but the overall sustainability.

Methods & Tools

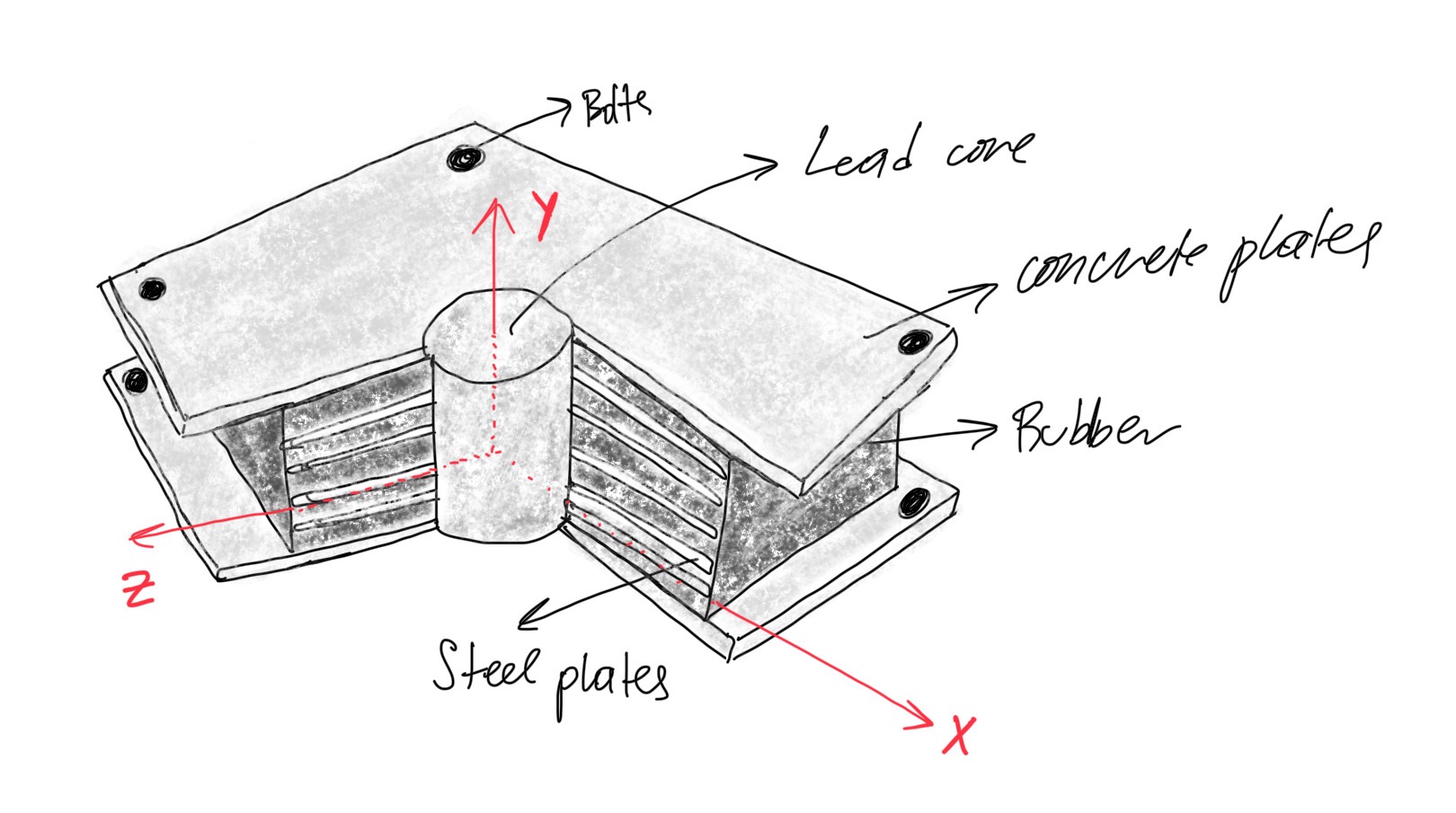

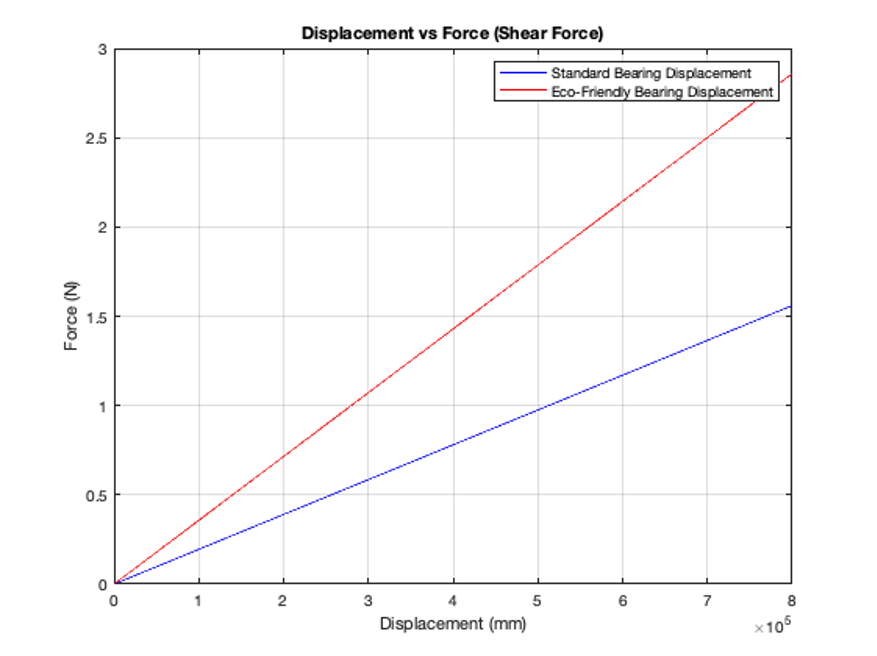

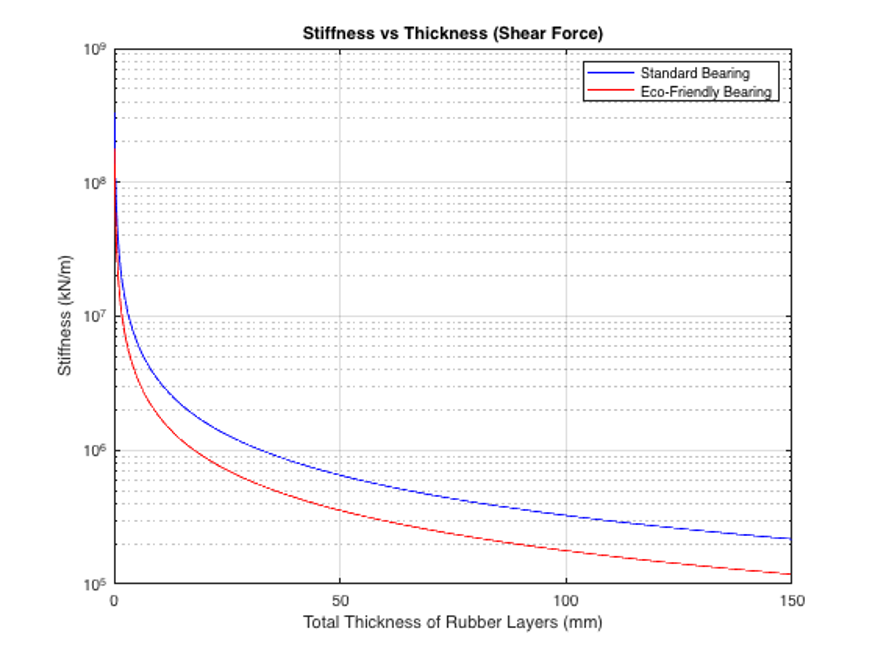

To analyze the differences in how natural rubber behaves compared to recycled automobile tires, Young’s modulus of elasticity, Stiffness of the material, Shear modulus, Shear stress, and Axial load will be used in the calculations. Young’s modulus describes how the material behaves under an axial load, mainly relating the stress imposed on the material to the strain of the material. Stiffness represents the relationship between the applied force and deformation. The analysis is based on the obtained values of Stiffness that can be used to compare the values and utilize the properties for further analyses, including how the bearing behaves in dynamic loading. For lateral forces, a numeral analysis is used using MatLab to account for the fact that seismic forces are dynamic. The values for Young’s module Shear module of STRP bearing are used from experimental data from “Low cost base-isolators from scrap tyre rubber pads”

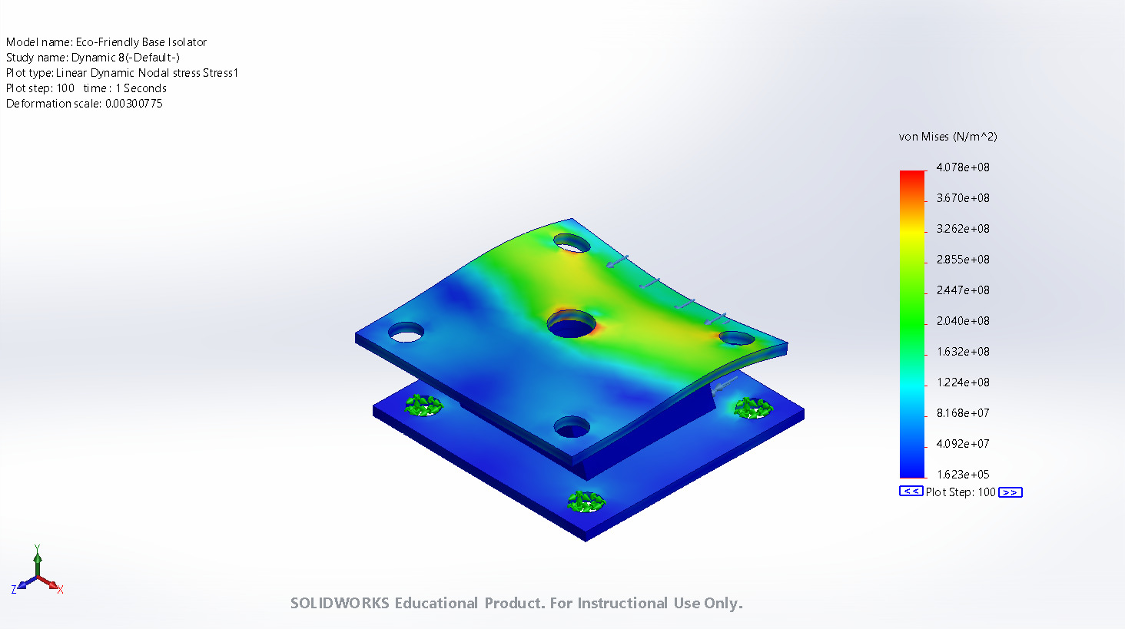

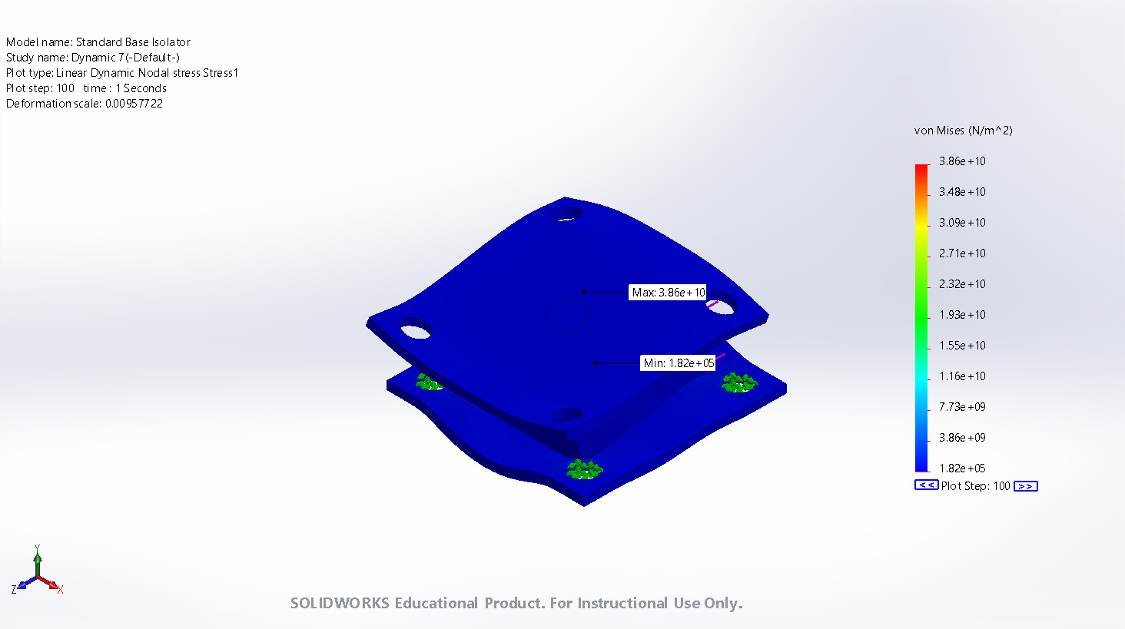

FEA Analysis using von Mises stress.

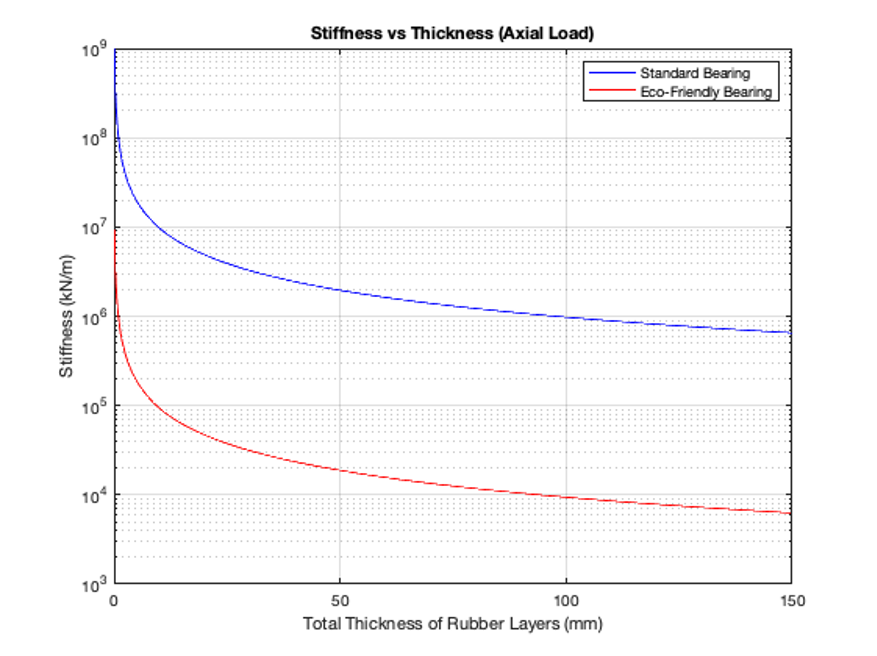

Stiffness comparison using MATLAB.

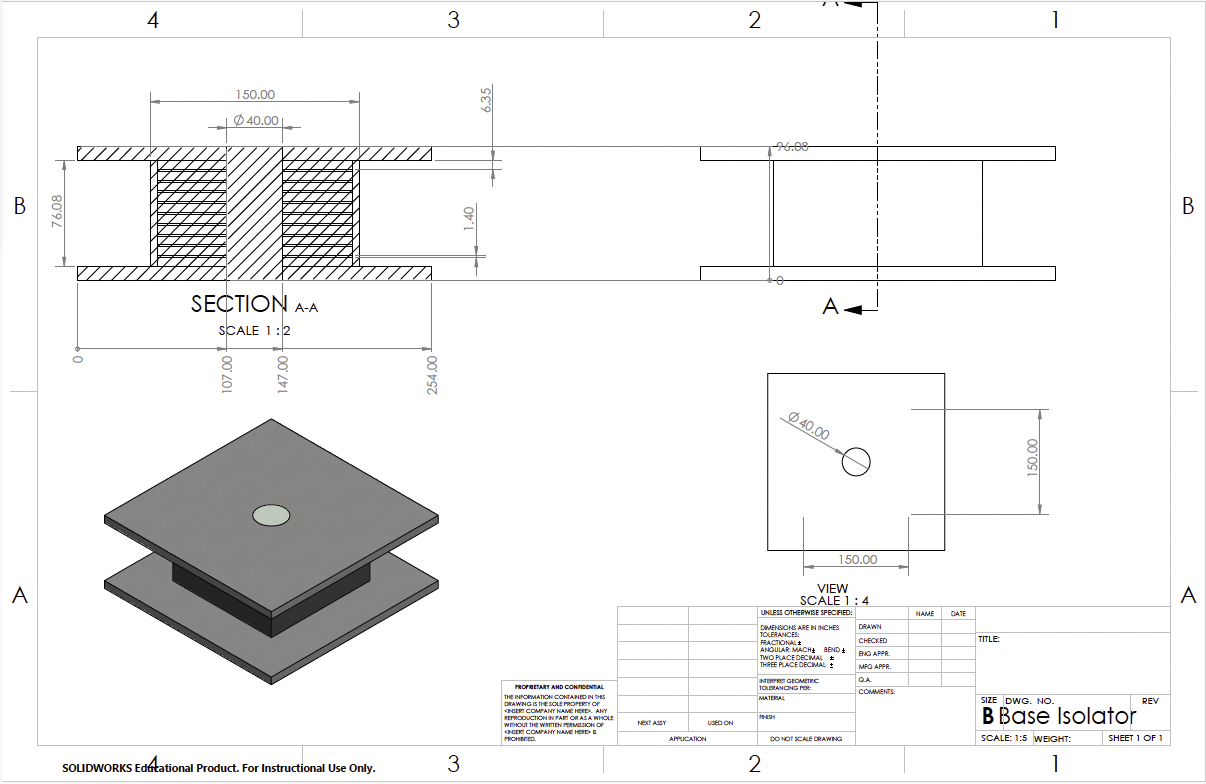

2D drawing of the Standard Base Isolator design.

Conclusion

While Eco-Friendly Base Isolators are promising in their effectiveness, they underperform their counterparts. STRPS have lower stiffness under both axial and shear loading. From Graph 1, the stiffness of the STRPS model drops significantly faster as the thickness of the rubber layers increases compared to the Standard model. Von Mises Stress Concentration illustrates that the maximum stress element for the Standard model is 3.86e+10N/m^2 while STRPS yields 4.078e+08N/m^2. Additionally, the max frequency in Hz for the Eco model was 0.78773 and 1.2707 for the Standard model, given a 38% difference. The stress concentration at the holes in the concrete plates for both models came up to be 2.00e+9N/^2, which is a larger max value for the Eco model but lower for the Standard model, indicating that the chosen size should have been larger. Standard Base Isolators are 94x more effective at absorbing stress concentration than STRPS. Some explanations for such differences could be explained by the fact that the Standard model has a concrete lead in the center that absorbs most of the axial loading, in addition, there are steel reinforcement plates distributed in between rubber layers that also act as reinforcement for axial loading that STRPS models miss. While the Eco model yields worse results than the Standard model by overcoming several issues in the design, such as adding a lead core and reinforming plates, it could result in better performance and thus wider implementation specifically for buildings of medium size. Thus, more analysis needs to be performed.